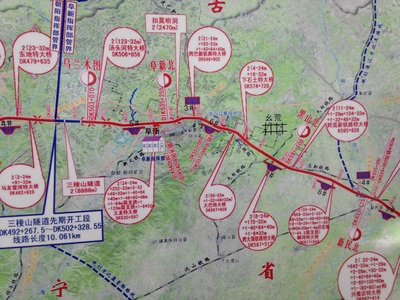

High Speed Rail is ramping up in the USA, in California. I had the unique experience of being afforded the opportunity to work on High Speed Rail in China (2014-2015), serving as Chief Site Engineer while working for TYLIN International. This page serves as an information springboard, exploring how China is able to so quickly build HSR, the processes and tools that are used. I was in responsible charge for overseeing all work processes on a 70 km HSR section, developing innovative visual inspection databases and reports, providing / overseeing formal instruction to ensure regular training of all engineers / workers, and coordinating and implementing rail authority directives with construction companies.

Grant Johnson, CSE

Grant Johnson, CSE

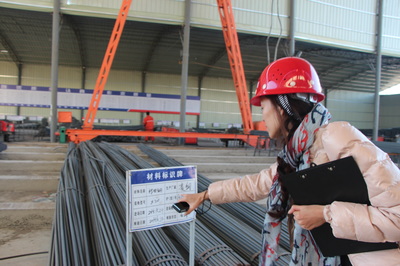

Inspection and Construction on Fuxin 70 km section: Pier, Tunnel, Rebar, Viaduct, Batching Plants

|

In the photos and videos that follow, I document the RAW experience, nothing sugar coated or pretended... this is how it was in the day to day experience on the ground and in the tunnels, and at the tops of high piers while inspecting and overseeing the construction of a 70 km portion of this massive and awe-inspiring project, the High Speed Rail between Beijing and Shenyang, a 700 km trip.

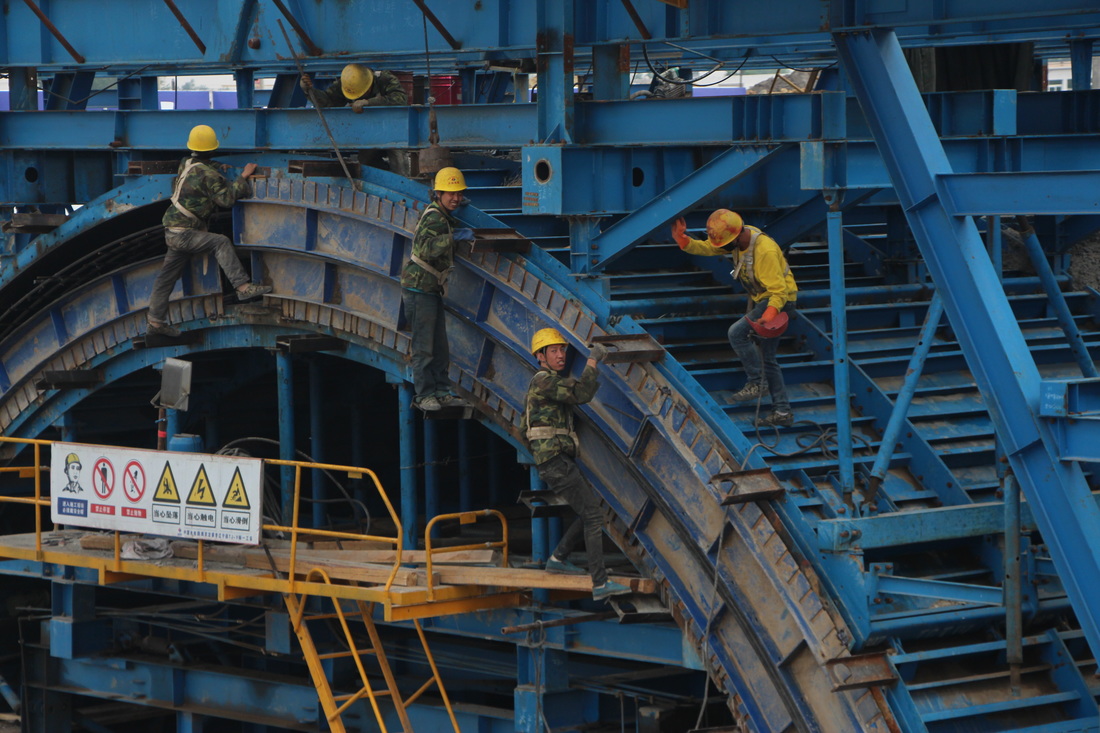

One thing that was apparent to me when comparing these construction processes with those taking place in say, the USA, is the predominance of lesser paid, lesser trained workers out on the ground and even on the scaffoldings. The cost is held way down and the speed of progress is very high. But safety is a constant issue, and even environmental and health concerns, especially in the tunnels where air quality is so bad it is dangerous without wearing a gas mask, and most do not wear a gas mask. There is this lack of concern, and I believe it has to do with education and concern on these matters. Observe-- |

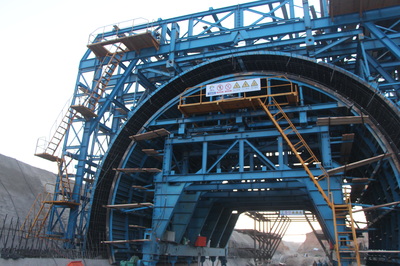

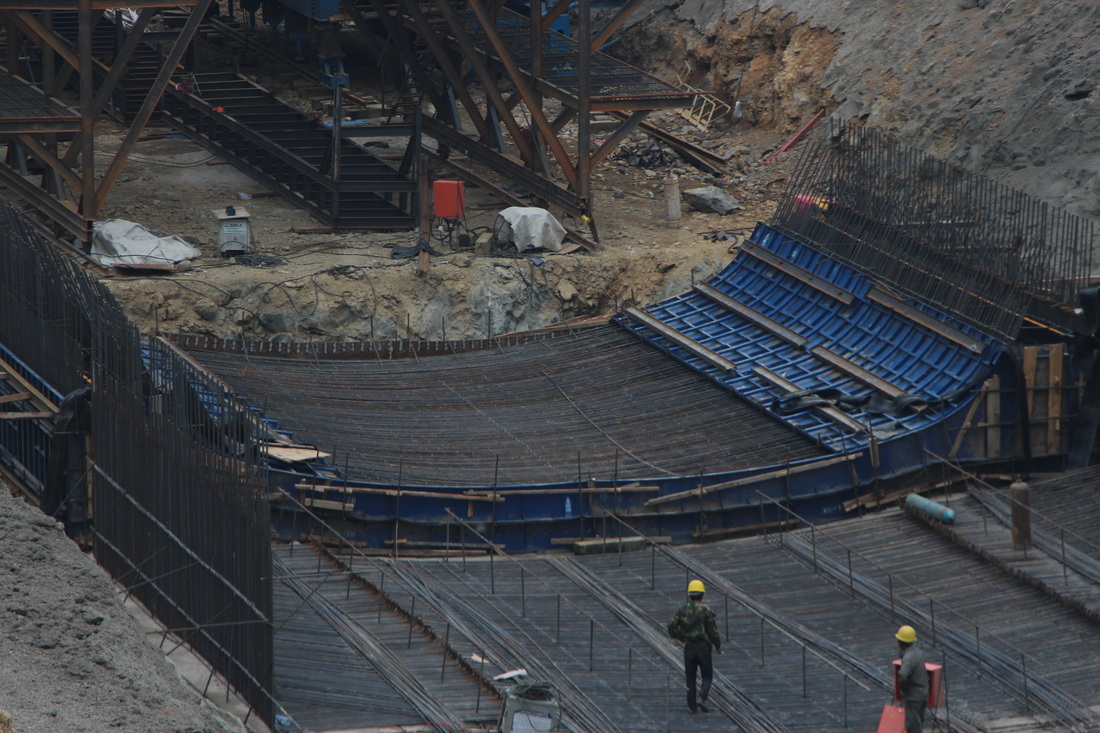

OPEN CUT TUNNEL Shell Construction, Concrete 12 meter length blue form mold surrounds rebar cage reinforcing. Rolls on temp rail track. Backfill when complete.

Preparation/cleaning of OPEN CUT TUNNEL MOLD prior to placing concrete (delivered by pump from truck on road). Final Product segment shown in photo below.

PILE construction, dig holes, remove earth expose/remove concrete, expose rebar cage hooks

|

|

|

|

FOUNDATION construction, weld pile rebar cage hooks to foundation block cage, ready for Phase 2 pour

Workers are assembling the rebar cage and connecting to the pile rebar (exposed). They will also create the rebar vertical extensions for the pier (see photo on right), which will not be covered in concrete at this step, but will be welded to and unified with the foundation rebar cage (shown). Then blue metal forms will be erected outside this cage of rebar and concrete filled throughout until just covering all rebar.

After foundation is poured and cured, which also had rebar extending upward (to be inside pier), the workers ready the rebar for fixing prior to installation of blue metal forms to create mold for pouring of concrete to the specified height of each pier. Concrete is pumped in by tube from crane. Piers will eventually support the viaduct girder bridge segments which are placed by massive crane, as viaduct segments weigh 800 tons each. All piers are equally spaced along the HSR track corridor, as all viaduct bridge segments are the same length, 32m.

Transition from Viaduct Bridge Piers to At-Grade HSR Track Foundation

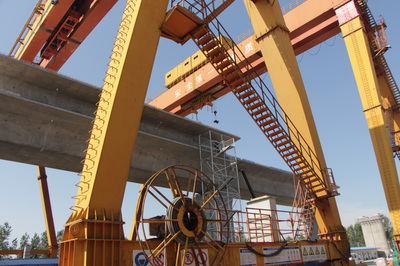

Girder Viaduct Bridge Segments Construction Yard-- The Process of Constructing 800 ton Viaduct Bridge Segments, each 32 meters in length.

China standardized viaduct construction techniques, to keep costs down. China built many viaduct sections so that farmland could be saved (see photos below) and to cross small rivers easily. At 32 meters in length each, these sections can be lifted up to the top of the tall track piers by a crane, lowered into place, and then using another crane, transport each lifted viaduct down to the next open 32 meter span between tall piers, lower it into place, secure, and then bring another viaduct bridge section up to the top and repeat. The length of trip from the construction yard is increased by 32 meters for each subsequent viaduct bridge section installed. After a while, it can take longer and longer to slowly roll each viaduct over long distances, exceeding miles.

Winter Prep. Temperatures fall so low, that construction must take a two month break

all photos and video © 2014-2015 Grant Johnson, all rights reserved