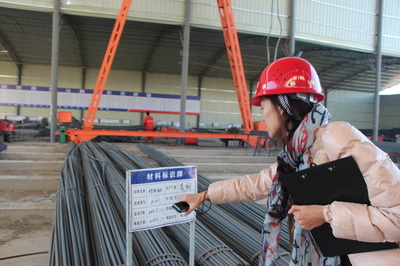

HSR construction inspection

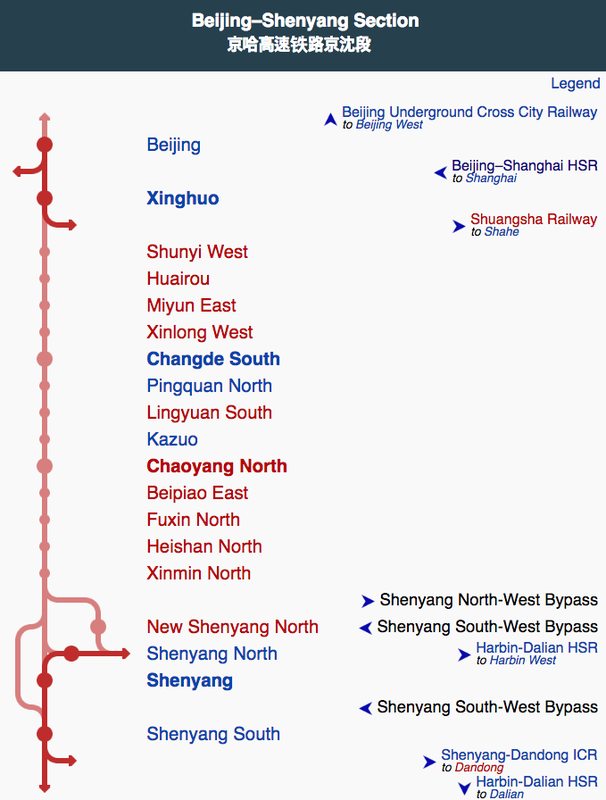

high speed rail

.

.

.

.

.

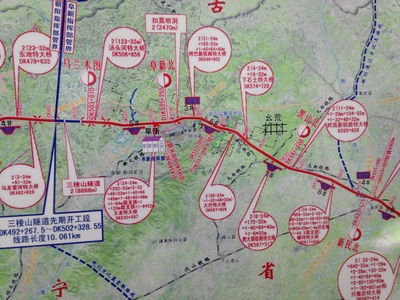

grant johnson, te was chief site engineer over 70 km section

of High Speed Rail construction from beijing to shenyang, china

.

.

.

.

grant johnson, te was chief site engineer over 70 km section

of High Speed Rail construction from beijing to shenyang, china